Quality team members account for 10% of the company's workforce, ensuring product quality

MES + management system, product specific QR code, transparent and traceable production process

Raw Material Inspection IQC

Raw Material Inspection IQCDelivery from raw material manufacturers

Warehouse inventory and receipt

IQC inspection

Making raw material identification cards

Raw material warehousing

Process inspection IPQC+finished product inspection QA

Process inspection IPQC+finished product inspection QAFirst piece production

First piece production confirmation

IPQC first article confirmation qualified

Mass production

IPQC process inspection

Shipping inspection OQC

Shipping inspection OQCShipping Notice

Packaging inspection product data

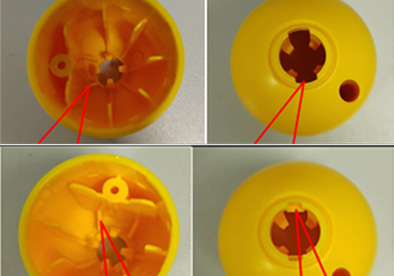

Visual inspection

OQC inspection

Make a logo

Six major laboratories provide strong support for product quality

Promote the quality concept of "zero defects" and create a quality culture environment of "doing things well the first time"